Author: admin

-

Hello world!

Welcome to WordPress. This is your first post. Edit or delete it, then start writing!

-

VISIO A/I 150

No bottle-to-bottle contact Neck handling direct drive gripper Heavy particles inspection station (side A) Heavy particles inspection station (bottom) Light particles inspecton station 1, 2, 3 Body cosmetic control Cap control Heavy particles inspection station (side B) Automatic rejection unit Back illumination system

-

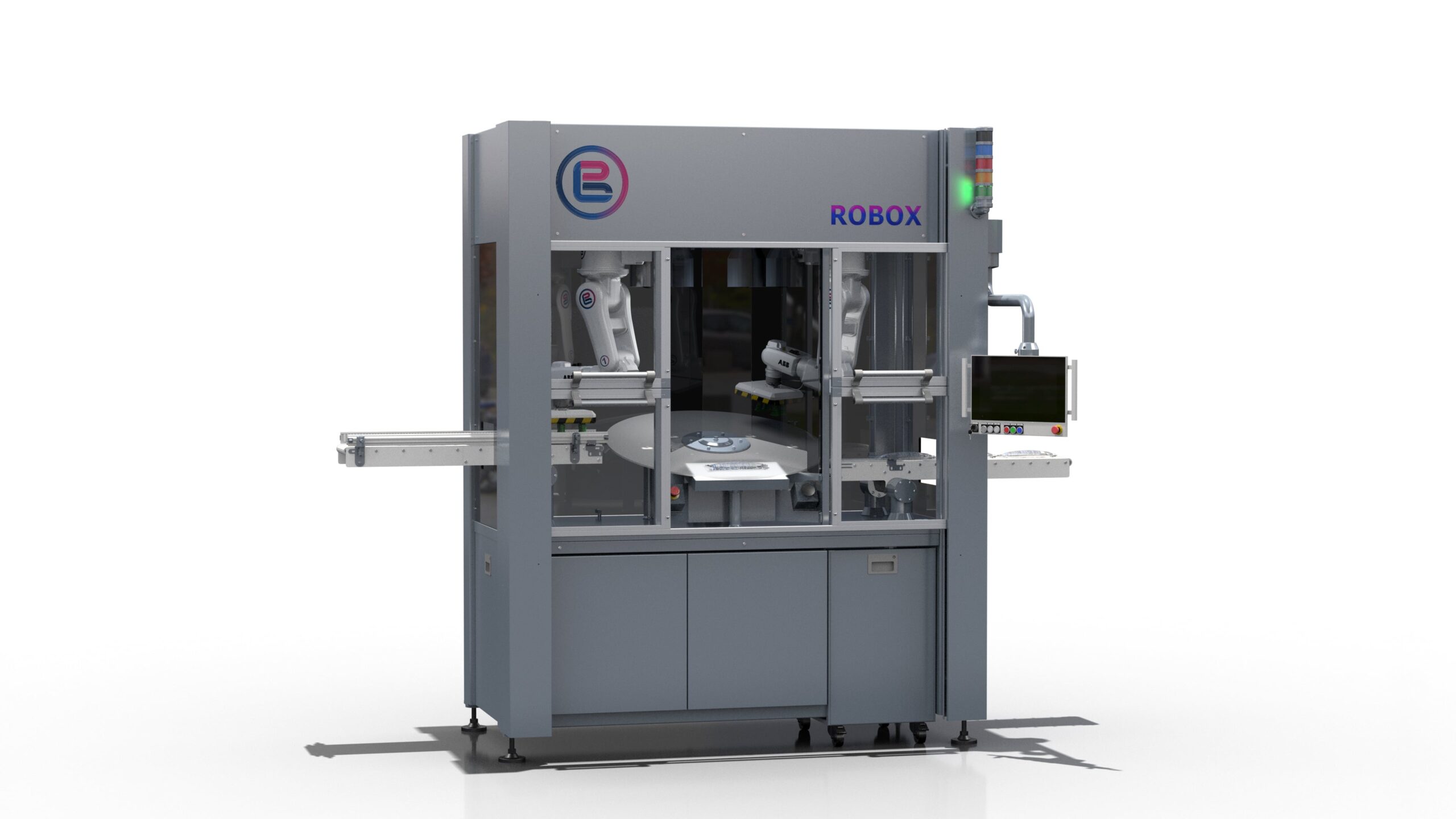

ROBOX A/I 20(M)

Robotic automatic bag loading system Station for human operator visual inspection Rear light illuminator Operators can safely touch the bags during inspection Option for robotic automatic rejection Robotic automatic bag unloading function Machine output : 15 to 300 BpM

-

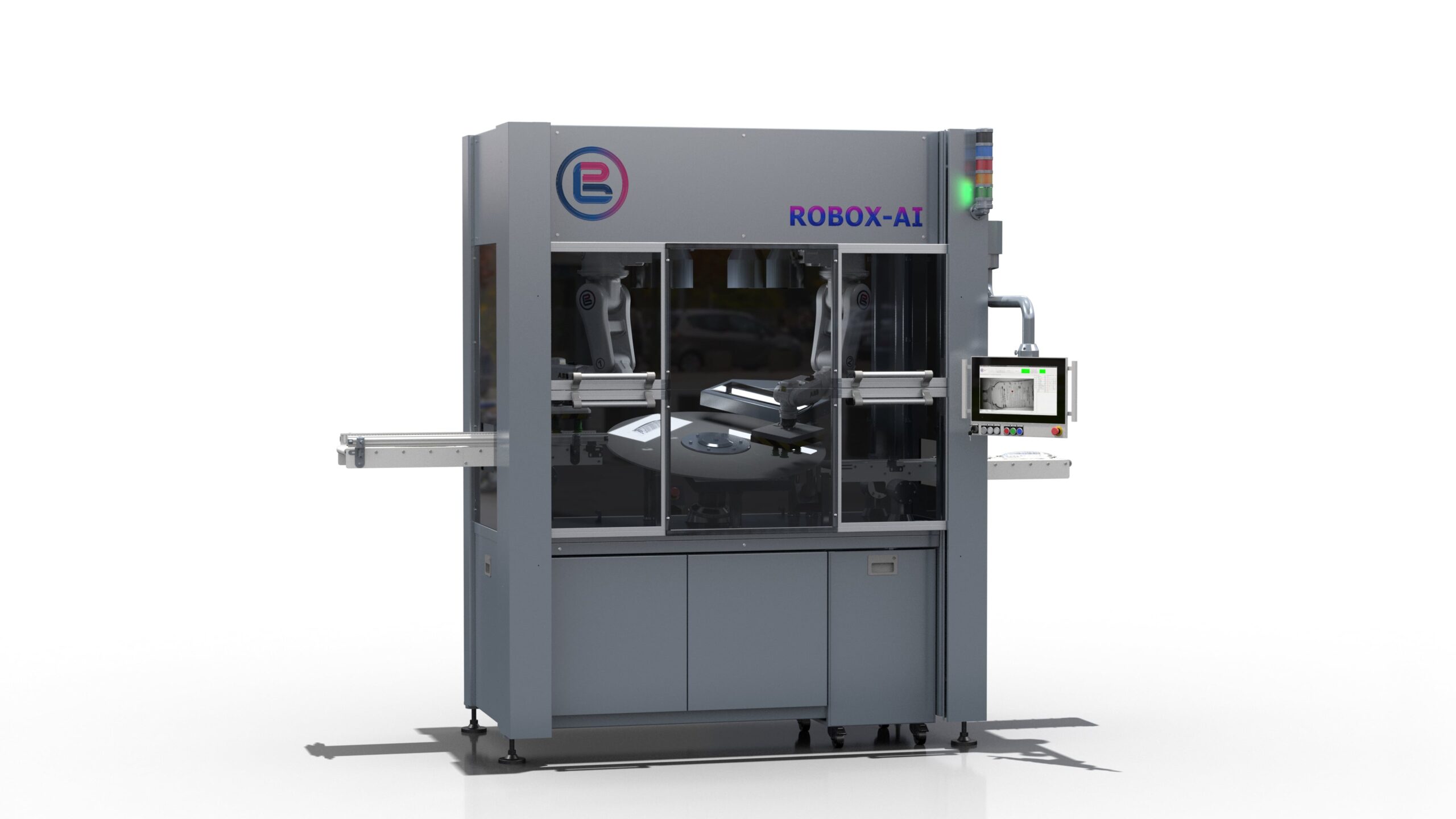

ROBOX A/I 20(A)

Robotic automatic bag loading system First station for automatic inspection (2 cameras) Rear light illuminator Second station for automatic inspection (2 cameras) Radiant light illuminator Patented inspection software supported by Deep Learning based on Artificial Intelligence Robotic automatic rejection Robotic automatic bag unloading function Machine output : 15 to 300 BpM

-

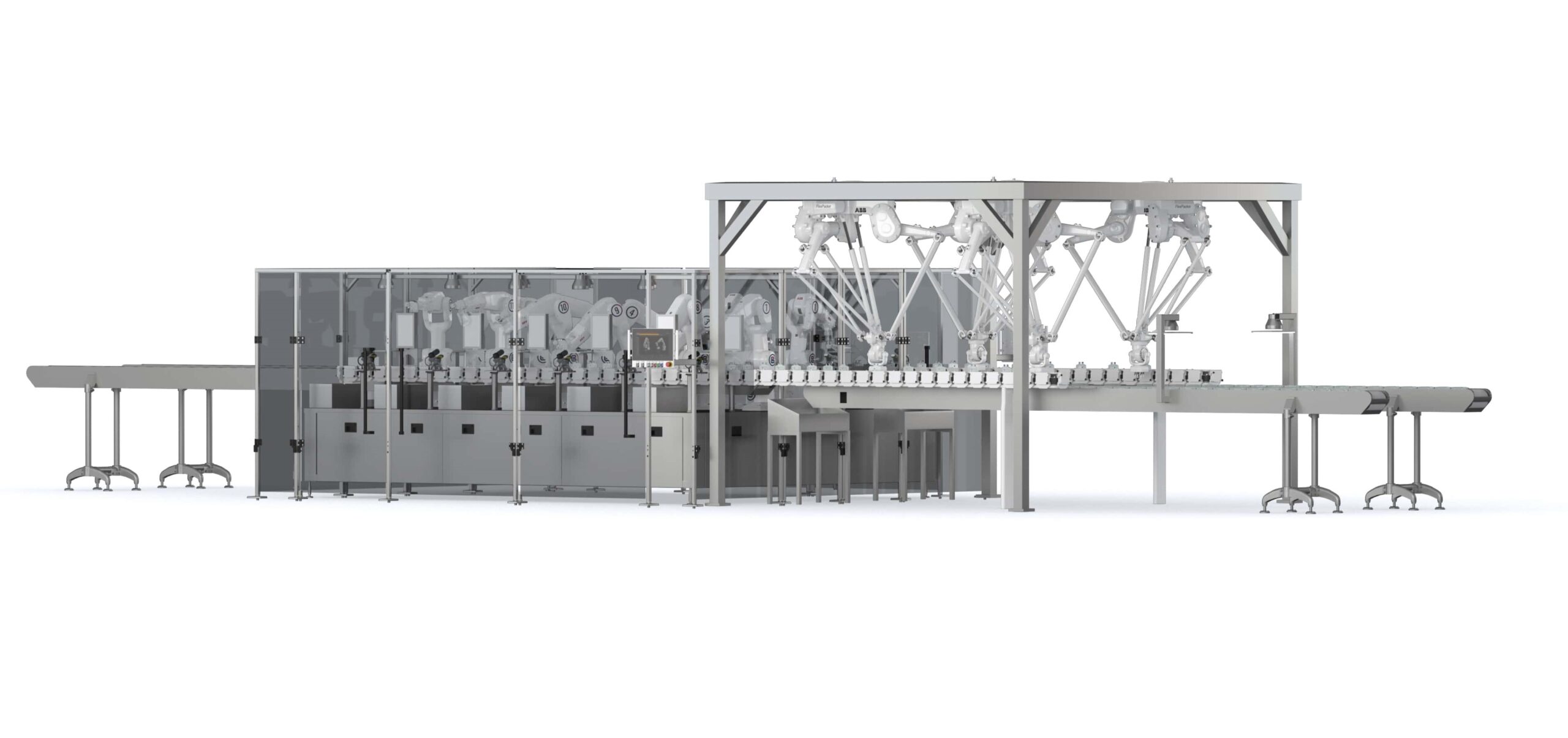

ROBOX A/I 240

Robotic automatic bag loading system First station for automatic inspection Rear and/or radiant light illuminator Second station for automatic inspection Barcode reader Inspection software supported by Deep Learning and Artificial Intelligence (Patented) Robotic automatic rejection Robotic automatic bag unloading system Machine output : 15 to 300 BpM

-

-

-

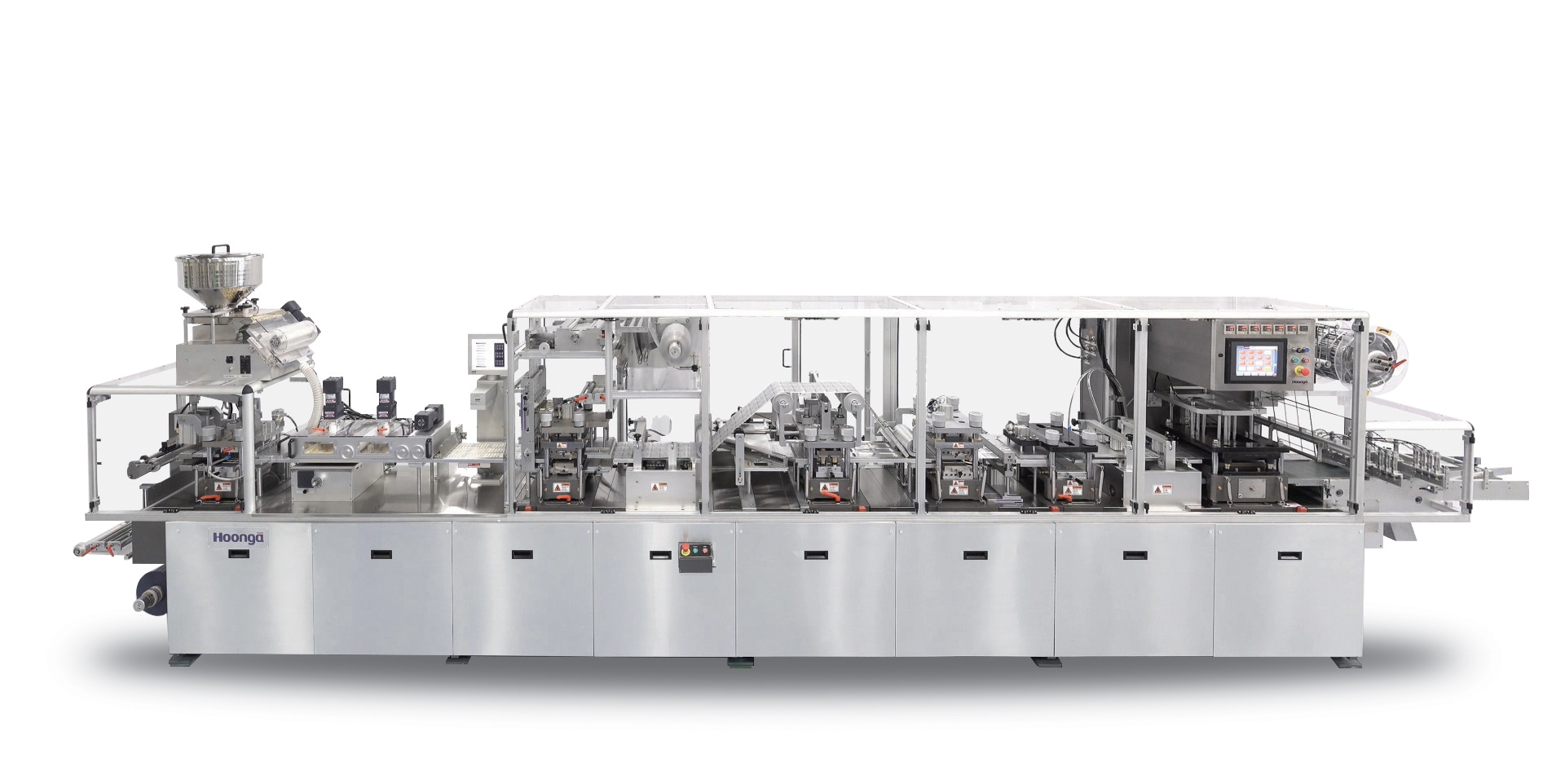

HM V6 TR

HM V6TR is a customized model of HM V6, specialized in tropical blister packaging to enhance the protection of humidity-sensitive product from temperature. This model has one more process to pack it with Tropical foil after PVC/Alu blister packaging. PLC control system and HMI touch screen Intermittent platen sealing Two forming stations for PVC/ALU and…

-

HM AV+

HM AV+ is a mechanical design blister packaging machine for liquid dose products, such as ampoules, vials, and syringes. This model is suitable for medium sized production with wide and deep forming range allowing flexible layout format. If necessary, feeding station can be extended with various systems, such as semi-automatic vertical magazine, automatic linear motion,…