Description

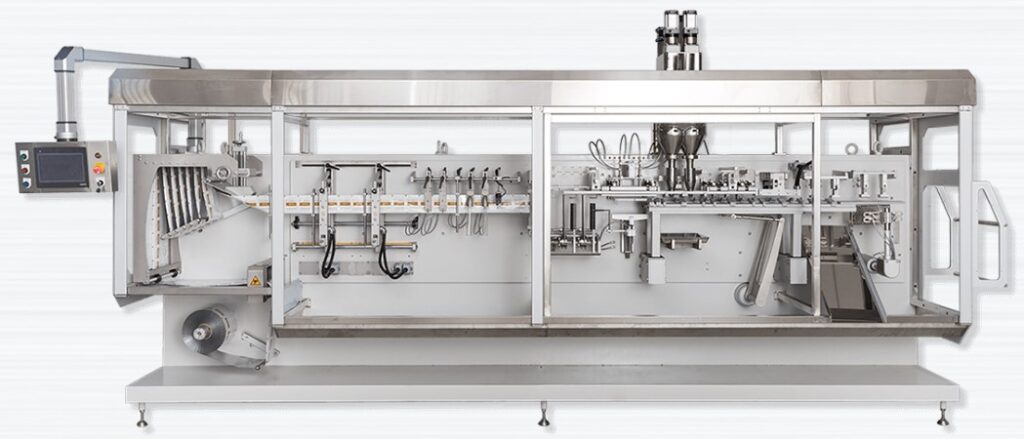

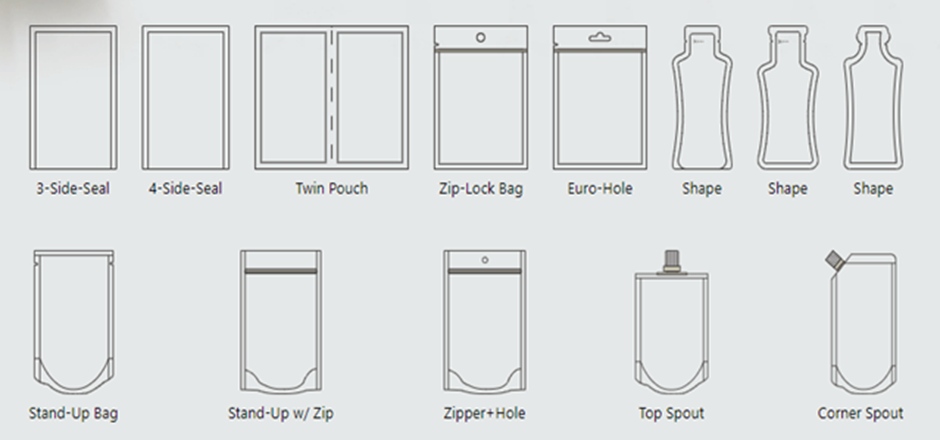

The horizontal form fill seal packaging machine offers a multi-functional design with high compatibility compared to other packaging machines. It is able to pack various types of products and materials using different filling systems, providing accurate filling for items such as powder, liquid, paste, solid, tablets, and capsules. The HFFS machine can help customers reduce labour costs, running costs, and production time while increasing efficiency. It is capable of producing different types of bags, including 3-sided sealed, 4-sided sealed, and stand-up bags with or without special shapes. Additionally, various sealing patterns such as cross, diamond, linear, or total flat are also available.

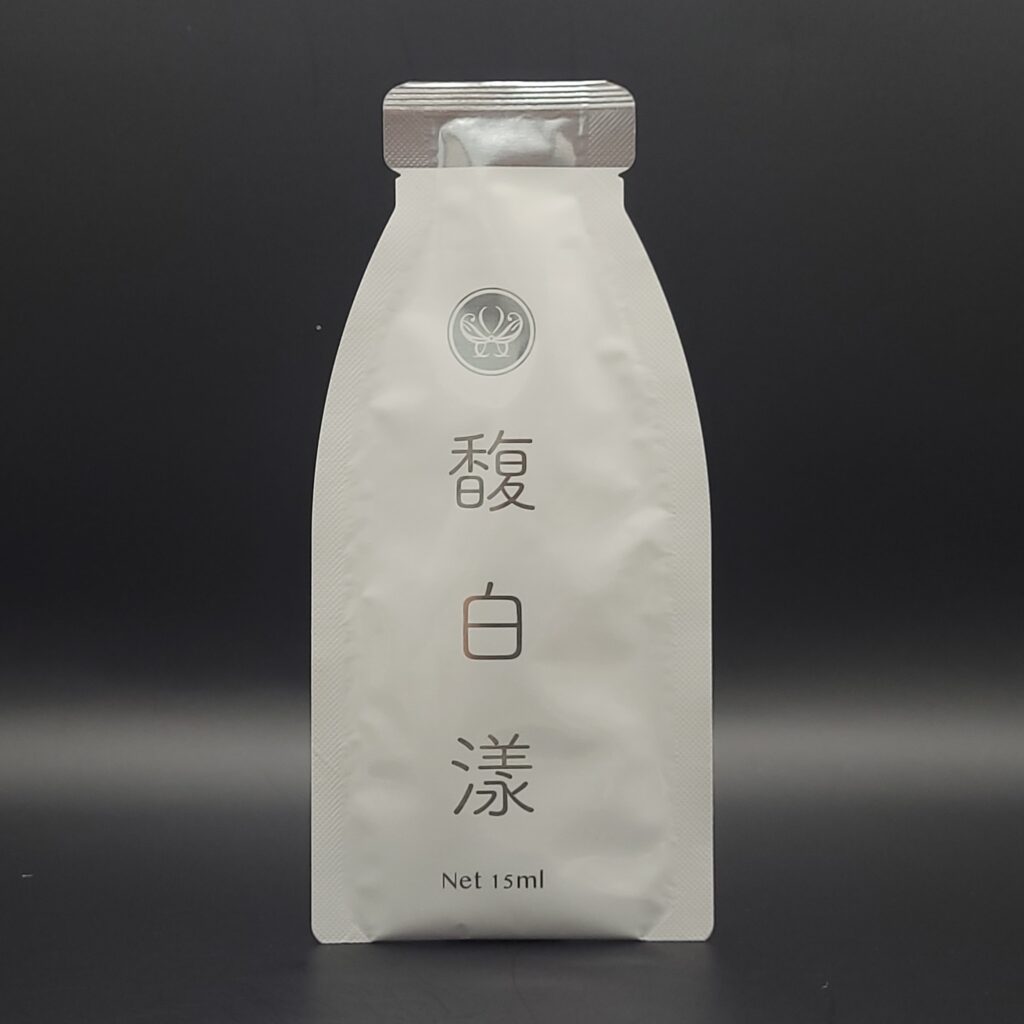

Liquid: Cosmetics, lotion, shampoo, cream, and detergent, essence, jelly, sauce, syrup, soup, steam rice, instant food, enzyme etc.

– Powder: collagen, protein, probiotics etc.

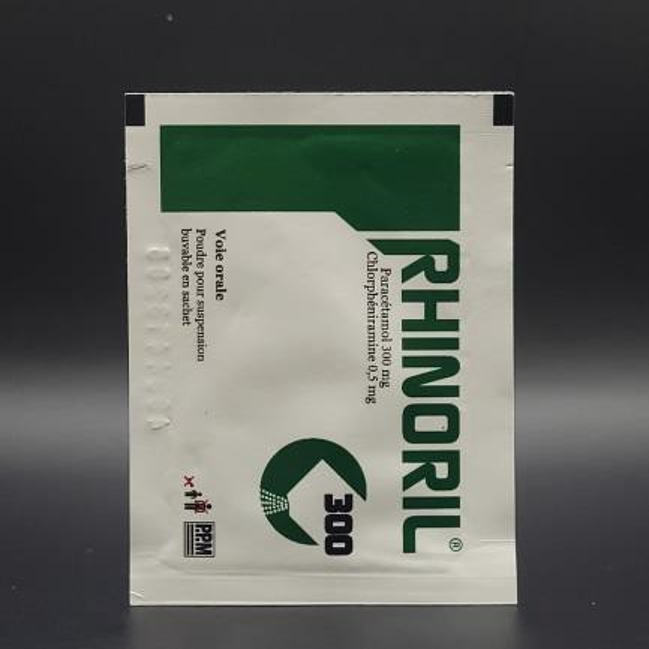

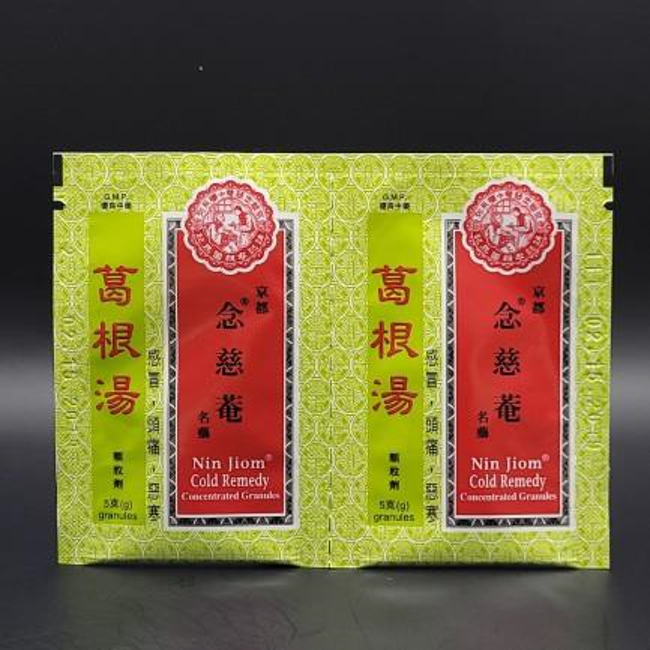

– Solid: capsules, tablets, granules etc.

Features

- Machine by Full CAM Design, running high speed with high stability.

- Servo Film Feeding System, High Accuracy regi-mark foils.

- Easy Size/Format Change within 45 minutes.

- Available with Servo Auger Filler, Cup Filler, Piston Filler, Vibratory Feeder, Multi-Head Weigher, etc.

- Including Hopper Level Detector available with Various kinds of Auto-Feeding System.

- Including Various Detect Function, like End of Reel, Jointed Tape, Hopper Level, Photo-Mark Fault, No Open/No Fill, Empty Pouch Reject.

- Optional: Auger Filler, Liquid & Paste Filler, Solid Vibratory System, Volumetric Cup Filler, Weighing Filling System, Tablet Counting/Filling, Capsule Counting/Filling etc.

Specification

| Pouch Type | 3-side, 4-side, twin pouch, zip lock, euro hole, shape, standup, standup with zip, spout with top or corner pouch etc. |

| Pouch Length | 60-300mm |

| Pouch Width | 50-280mm |

| Speed | 30-240 pouches/min |

**Above machine is customised machine and specification of machine varies as per user requirements

Sample Output